Non-ferrous metals have shone in various fields of modern society due to their unique physical and chemical properties. In the aerospace field, titanium alloy has become the core material for manufacturing aircraft fuselage and engines due to its high strength, low density, and good high temperature resistance; In the electronic information industry, high-purity copper is widely used in circuit board and chip manufacturing due to its excellent conductivity and thermal conductivity; New energy vehicles cannot do without non-ferrous metals such as lithium and cobalt, which greatly enhance the energy density and endurance of the battery.

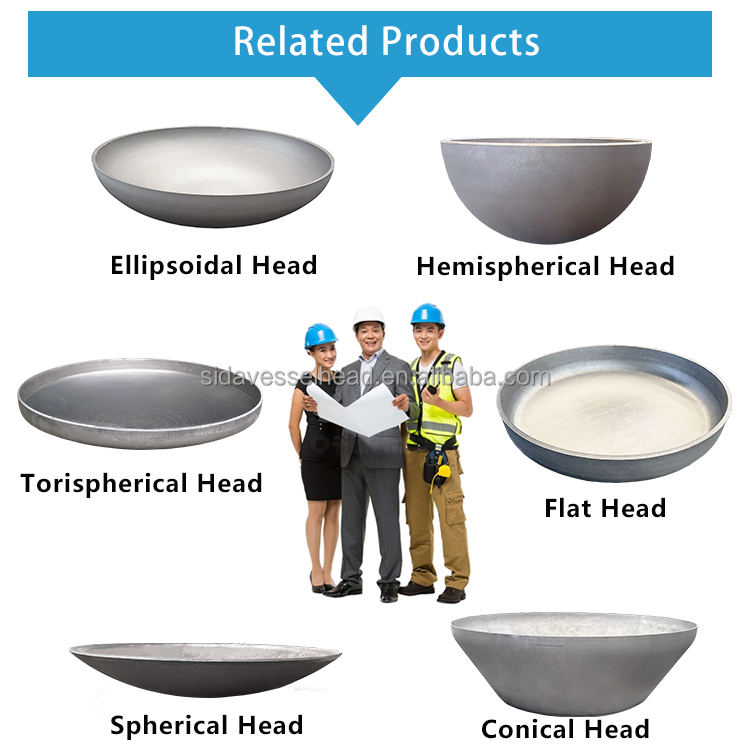

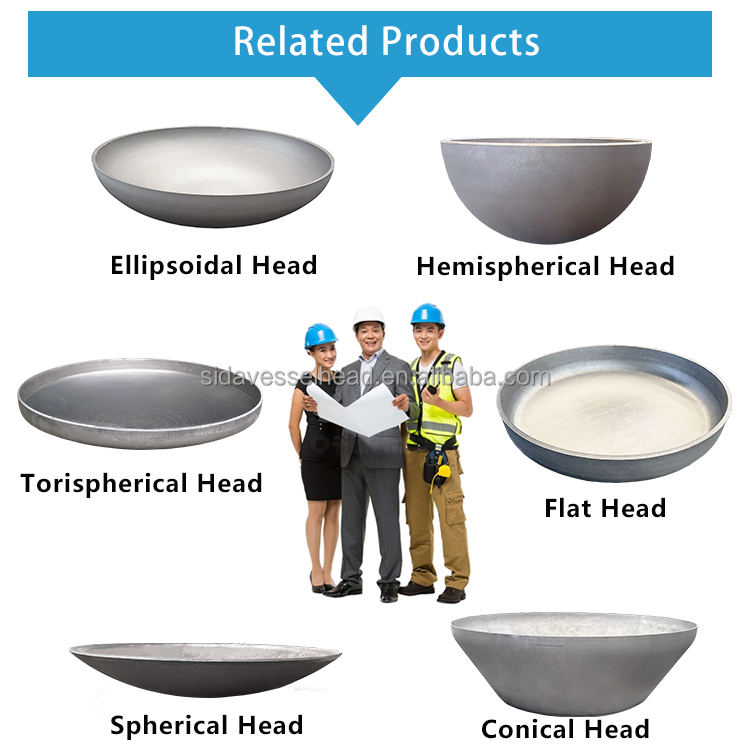

In the field of head manufacturing, non-ferrous metals also play a crucial role. The nuclear power, chemical, aerospace and other industries have extremely high requirements for the corrosion resistance, high temperature resistance and strength of the head. Heads made of non-ferrous metals such as titanium and nickel-based alloys, with excellent chemical stability and mechanical properties, can operate stably in extreme environments, meeting the stringent requirements of these top-tier industries and becoming key components to ensure equipment safety and efficient operation.

Sida Head is a head source factory that focuses on providing you with high-quality customized services for non-ferrous metal heads to meet your diverse needs.

Strong technical strength, meeting customer needs

Sida Head has rich experience in head processing and production. The factory is equipped with a 3000-ton stamping machine, 6.5-meter metal spinning machine, CNC polishing machine, and plasma automatic welding system, achieving full process automation from cutting, forming to surface treatment, and ensuring the accuracy and consistency of non-ferrous metal heads. In response to the difficulties of easy oxidation of titanium materials and hardening of nickel-based alloys, Sida has improved product performance through vacuum heat treatment, cold spinning process optimization, and surface passivation treatment, meeting the strict standards of nuclear industry, aerospace and other fields.

Providing product customization, cracking industry pain points

In response to diverse customer needs, Sida Head provides "customized drawings" and "customized samples" services. Through in-depth communication with customers to understand usage scenarios, technical parameters, performance indicators, and other details, Sida Head quickly responds to non-standard head orders with abundant mold resources and flexible production capabilities, greatly shortening delivery cycles, saving customers’ time and costs, and boosting project.

Sida Head is always committed to providing customers with high-quality head products, responding to every expectation with quality. In the future, driven by innovation and based on quality, Sida Head will continue to deepen its cultivation in the field of head manufacturing and continuously improving its technological level and service quality. We also look forward to joining hands together with more enterprises to promote the development of China’s manufacturing industry and jointly write a new chapter in industrial manufacturing.

English

English 日本

日本 한국인

한국인 Français

Français Deutsch

Deutsch español

español Italiano

Italiano Portugal

Portugal Việt Nam

Việt Nam türkiye

türkiye عرب

عرب Русский

Русский čeština

čeština แบบไทย

แบบไทย Eesti

Eesti Gaeilge

Gaeilge Hmoob

Hmoob íslenskur

íslenskur Cymraeg

Cymraeg български

български اردو

اردو Polski

Polski Hrvatski

Hrvatski українська

українська bosanski

bosanski فارسی

فارسی lietuvių

lietuvių latviski

latviski עִברִית

עִברִית Română

Română Ελληνικά

Ελληνικά dansk

dansk Magyar

Magyar norsk

norsk Suomalainen

Suomalainen Nederlands

Nederlands svenska

svenska slovenský

slovenský Slovenščina

Slovenščina हिंदी

हिंदी Indonesia

Indonesia Melayu

Melayu Malti

Malti Kreyòl ayisyen

Kreyòl ayisyen català

català বাংলা

বাংলা Српски

Српски o'zbek

o'zbek